Create a Socket With a Seamless Connection Between HCR Silicone Rubber and Hard Resin Laminate

To conjoin materials as dissimilar in their properties as elastic rubber and rigid resin laminate is questionable from an engineering standpoint. Yet with a certain fabrication approach, along with a sound mechanical transitional connection, an apparently seamless, durable transition from resin to rubber is achievable. This article describes how to create a hybrid socket with conventional hard laminated resin along with a special kind of silicone rubber.

To conjoin materials as dissimilar in their properties as elastic rubber and rigid resin laminate is questionable from an engineering standpoint. Yet with a certain fabrication approach, along with a sound mechanical transitional connection, an apparently seamless, durable transition from resin to rubber is achievable. This article describes how to create a hybrid socket with conventional hard laminated resin along with a special kind of silicone rubber.

To date, our practice has only focused on upper-limb applications for this technique. However, this experience opens a rich territory of new socket and appliance designs for orthoses and prostheses. Moreover, when one realizes that products with this combination of materials are relatively easy to produce, such applications may gain widespread acceptance.

The essential processing technique for high consistency rubber (HCR) silicone is beyond the scope of this article, but a basic fabrication manual on HCR silicone is available from the supplier we use, Factor II, Lakeside, Arizona. For additional hands-on classes in HCR fabrication, contact the International Center of Education for the Advancement of Silicone Prosthetics at www.iceasp.com.

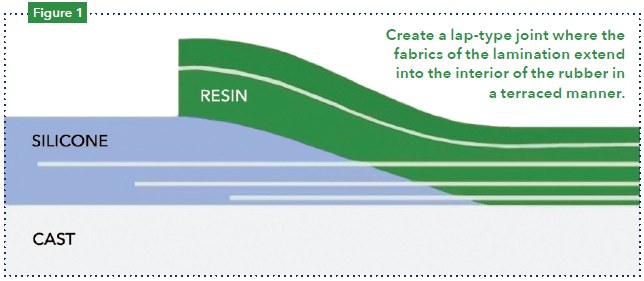

Epoxy-acrylic resin and silicone do not have good properties for chemical bonding. Therefore, they require using another strong fabric material, Spectralon, during fabrication to create a bond. Spectralon is incorporated into the lap-type joint, which can withstand the high local stress associated with unavoidable bending at the joint. The fabric has a progressively terraced insertion into the rubber to distribute forces acting across the joint over a large area. Resin, wicking into these strata, penetrates somewhat into the interior of the rubber at these layers to enhance the mechanical connection.

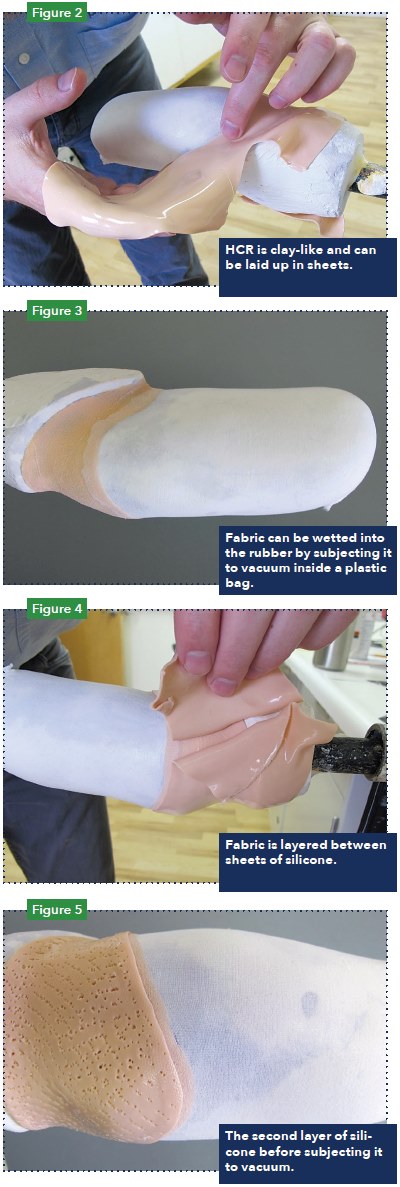

HCR rubber is used because of its extraordinary strength. A variety of durometer formulations that can be simply formed into precise shapes are available. HCR rubber is catalyzed and conditioned by means of a calendering tool. The calendering tool is essentially a two-roller mill and may be difficult to find, but it is available from Factor II.

Materials and Tools

Materials and Tools

With the exception of the calendering device and the HCR silicone, all the materials needed to create the hybrid socket are readily available and common in a prosthetic fabrication lab.

Materials

• Plaster cast

• HCR silicone

• Silicone pigment

• PVA cast sealant

• Polyester parfilm

• Clear plastic bags

• Spectralon hose

• Sheer nylon hose

• Epoxy/acrylic resin

• Additional laminating fabric of choice

Tools

• Knurled hand tool and smooth cylinder for rolling

• Calendering two-roll mill

• Low-temperature oven

• Vacuum pump

• Conventional laminating supplies

• Pinwheel

Building the Connection

Support authors and subscribe to content

This is premium stuff. Subscribe to read the entire article.