Massachusetts Institute of Technology (MIT) engineers have found a new approach to creating artificial muscle fibers that reproduce some of the bending motions that natural muscle tissues perform. They are using nylon fiber as a key ingredient. Artificial muscles-materials that contract and expand somewhat like muscle fibers do-can have applications from the automobile and aviation industries to robotics.

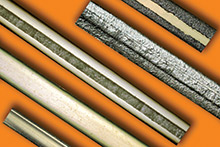

This image shows the fabrication steps starting with raw circular filament (bottom sample). Researchers press the filament using a rolling mill (the second sample from the bottom). Next, they add a mask in the middle of the surface (the third sample from the bottom). Then, they add the conductive ink (the second sample from the top). Finally, they remove the mask after the ink is dried (the sample on the top).

Image by Felice Frankel and Seyed Mohammad Mirvakili, courtesy of MIT.

The new approach to harnessing the synthetic fiber material lies in shaping and heating the fibers in a particular way, which is described in a paper in the journal Advanced Materials by Seyed Mirvakili, a doctoral candidate, and Ian Hunter, PhD, the George N. Hatsopoulos professor in thermodynamics, in the MIT Department of Mechanical Engineering.

Researchers had previously developed the principle of using twisted coils of nylon filament to mimic basic linear muscle activity. They showed that for a given size and weight, such devices could extend and retract further, and store and release more energy than natural muscles. But bending motions, such as those of human fingers and limbs, proved more challenging and had not yet been achieved using a simple manufacturing process and inexpensive material until the new work at MIT. The new nylon-based system also has cycling longevity-the researchers demonstrated that the material can maintain its performance after at least 100,000 bending cycles, and can bend and retract at a speed of at least 17 cycles per second.

Some polymer fiber materials, including highly oriented nylon, have an unusual property: When heated, “they shrink in length but expand in diameter,” Mirvakili said, and this property has been harnessed to make some linear actuator devices. But to turn that linear shrinking motion into bending typically requires a mechanism such as a pulley and a take-up reel, adding extra size, complexity, and expense. The MIT team’s advance was to directly harness the motion without requiring extra mechanical parts.

The team started with ordinary nylon fishing line and compressed it to change its cross-section from round to rectangular or square. Then, selectively heating one side caused the fiber to bend in that direction. Changing the direction of the heating could also produce more complex motions; in their lab tests, the team used this heating technique to get the fibers to move in circles and figure eights, and much more complex patterns of movement could be achieved, they said.

Editor’s note: This story was adapted from materials provided by Massachusetts Institute of Technology.