Two teams of undergraduate engineering students at Michigan Technological University (MTU), Houghton, have developed two low-cost, workable prostheses-one a knee, one a foot-and brought them to India, the first step in an effort to make them available to low-income individuals with amputations who live in India. They have also applied for patents on both devices.

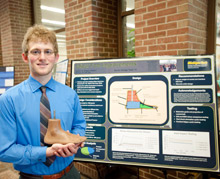

Ryskamp led a team of MTU seniors in developing a low-cost prosthetic knee. Photographs courtesy of Michigan Technological University.

As part of their International Senior Capstone Design, a program based in the Department of Mechanical Engineering-Engineering Mechanics, the two teams have been working since fall 2011 to develop prosthetic devices that are affordable and lightweight; made with local materials and by local labor; easy to assemble, adjust, and repair; and allow for a natural gait. Teams also had to consider the Indian culture and design devices that would accommodate common practices, such as sitting cross-legged and squatting, and suit people who often wear sandals or go barefoot.

Kelsy Ryskamp, who is working on a dual major in mechanical engineering and biomedical engineering, was on the knee team that traveled to Jaipur and New Delhi to meet orthopedic surgeons over spring break. “They were impressed with our work,” she says. “It’s amazing we had this opportunity, and it’s crazy to think that a group of six students could do something this big-potentially change the way people live in a developing country. We started with basically nothing,” she said. “We had creative license to do what we wanted.”

Ryskamp says the students’ model, which is the same size as a human knee, would cost $510 and is designed to be sturdy. Students tested stresses, creep and deformation, and aesthetics. The knee comes in three sizes, all for adults. The prototype was completed in March, and refinements were made after the ten-day spring break trip to India. It is now being tested at the All India Institute of Medical Science, New Delhi.

“It was easy for us to get inspired and work hard,” said Kerkove, who lead the team that was improving the Jaipur foot. “The expectations were high. Everyone was motivated to try and help people over there [in India].”

Marcel Kerkove, a senior in mechanical engineering, worked on a prosthetic foot with five other students. They, too, trekked to India in March to present their artificial foot-an adaptation of the Jaipur foot-to surgeons at the Santokba Durlabhji Memorial Hospital, Jaipur.

Their charge was to design a prosthesis that is lightweight and costs less than $50 to build. They realized both: the device weighs less than an actual foot, and it can be built for $18 (this in a country where a laborer earns $5 a day). Kerkove said the foot is reliable and has a life cycle of three years. “There’s nothing on it that will stop working,” he said. It is meant to affix to a prosthetic leg with a single bolt.