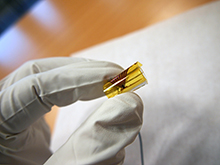

The new optical circuit works when bent around an object about the diameter of a human finger. Photograph courtesy of Centre for Microsystems Technology/imec/Ghent University.

A team of Belgian researchers have developed what they say may be the first optical circuit that uses interconnections that are not only bendable, but also stretchable. By integrating these stretchy interconnections into a circuit-with a light source on one end and a detector on the other-the researchers created a miniature stretchable, bendable “link” that could be incorporated into optical communications systems. Future uses for the new optical link might include building networks of wearable body sensors, moving machine parts such as robotic limbs, and deformable consumer electronics. The results were published online February 18 in The Optical Society’s (OSA) open-access journal Optics Express.

These new interconnections, made of a rubbery transparent material called PDMS (polydimethylsiloxane), guide light along their path even when stretched up to 30 percent and when bent around an object the diameter of a human finger. Previously, researchers had created optical interconnections, also called lightguides or waveguides, from other similar rubbery materials. But until now, the researchers say, no one had discovered a way to enable these materials to carry light while stretched. Past efforts also included embedding waveguides made of semi-rigid glass fibers into a stretchable substance. In the new method, the stretchable substance itself is the waveguide.

The new connector consists of two materials, both made of PDMS: a transparent core through which the light travels, surrounded by another transparent layer of PDMS with a lower refractive index, a characteristic of the material that describes how light moves through it. This configuration traps light in the guide’s core, causing it to propagate along its length.

Bending a waveguide beyond a certain point causes some of the light trapped in the core to escape, a process called optical loss. The Belgian team tested how far they could bend and stretch their new optical connector before too much light escaped. The researchers did not see a degradation in the material even after mechanically stretching it to a 10 percent elongation 80,000 times.

The team said it plans to make its waveguide smaller, down from 50 micrometers to just a few micrometers in diameter, which will also require a redesign of the parts of the waveguide where light enters and exits.

Editor’s note: This story was adapted from materials provided by OSA.