Using a novel fabrication process, researchers at the Massachusetts Institute of Technology (MIT) produced smart textiles that snugly conform to the body to sense the wearer’s posture and motions. By incorporating a special type of plastic yarn and using heat to thermoform it, the researchers were able to improve the precision of pressure sensors woven into multilayered knit textiles, which they call 3DKnITS.

The high accuracy of 3DKnITS could make them useful for applications in prosthetics, including a smart textile liner that could measure the pressure a prosthetic limb places on the socket, enabling a prosthetist to easily see how well the device fits, said Irmandy Wicaksono, a research assistant in the MIT Media Lab and lead author of a paper presenting 3DKnITS.

The researchers used the process to create a smart shoe and mat, then built a hardware and software system to measure and interpret data from the pressure sensors in real time. The machine-learning system predicted motions and yoga poses performed by an individual standing on the smart textile mat with about 99 percent accuracy.

The technique could have many applications in healthcare and rehabilitation, such as to produce smart shoes that track the gait of someone learning to walk again after an injury, or socks that monitor pressure on the foot of a patient with diabetes to prevent the formation of ulcers.

“With digital knitting, you have this freedom to design your own patterns and also integrate sensors within the structure itself, so it becomes seamless and comfortable, and you can develop it based on the shape of your body,” Wicaksono said.

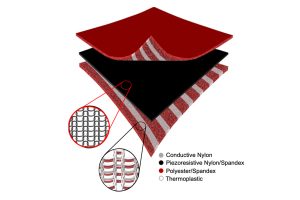

The multilayer knit textile is composed of two layers of conductive yarn knit sandwiched around a piezoresistive knit, which changes its resistance when squeezed. Following a pattern, the machine stitches this functional yarn throughout the textile in horizontal and vertical rows. Where the functional fibers intersect, they create a pressure sensor. However, since yarn is soft and pliable, the layers shift and rub against each other when the wearer moves, which generates noise and causes variability that make the pressure sensors much less accurate. To correct for this, Wicaksono decided to incorporate melting fibers and thermoforming into the smart textile fabrication process.

“The thermoforming really solves the noise issue because it hardens the multilayer textile into one layer by essentially squeezing and melting the whole fabric together, which improves the accuracy. That thermoforming also allows us to create 3D forms, like a sock or shoe, that actually fit the precise size and shape of the user,” he said.

Once the model was trained, it could classify the user’s activity on the smart mat (walking, running, doing push-ups, etc.) with 99.6 percent accuracy and could recognize seven yoga poses with 98.7 percent accuracy.

The research team also used a circular knitting machine to create a form-fitted smart textile shoe with 96 pressure-sensing points spread across the entire 3D textile. They used the shoe to measure pressure exerted on different parts of the foot when the wearer kicked a soccer ball.

Currently, the model must be calibrated to each individual before it can classify actions, which is a time-consuming process. Removing that calibration step would make 3DKnITS easier to use. The researchers also want to conduct tests on smart shoes outside the lab to see how environmental conditions like temperature and humidity impact the accuracy of sensors.

Editor’s note: This story was adapted from materials provided by MIT.

The paper, “3DKnITS: Three-dimensional Digital Knitting of Intelligent Textile Sensor for Activity Recognition and Biomechanical Monitoring,” will be presented at the IEEE Engineering in Medicine and Biology Society Conference in September.