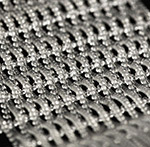

UT Dallas scientists produced the fibers in this woven textile by highly twisting nylon sewing thread to produce coiled artificial muscles. Photograph courtesy of UT Dallas.

Researchers at The University of Texas at Dallas (UT Dallas) and the University of Wollongong, Australia, have put a high-tech twist on fiber spinning, using modern materials to create ultrastrong, powerful, shape-shifting yarns. In a perspective article published online September 26 in the Proceedings of the National Academy of Sciences (PNAS), a team of scientists at UT Dallas’ Alan G. MacDiarmid NanoTech Institute describes the path to developing a new class of artificial muscles made from highly twisted fibers of various materials, ranging from carbon nanotubes to nylon thread and polymer fishing line. Because the artificial muscles can be made in different sizes and configurations, potential applications range from consumer products, such as smart textiles that change porosity and shape in response to temperature, to robotics and prostheses.

“We call these actuating fibers ‘artificial muscles’ because they mimic the fiber-like form-factor of natural muscles,” said Carter Haines, PhD, associate research professor in the NanoTech Institute and co-lead author of the article, with research associate Na Li, PhD.

Haines and Li’s work is built on prior work that was led by Ray Baughman, director of the NanoTech Institute and the Robert A. Welch Distinguished Chair in Chemistry at UT Dallas. In 2004, Baughman and his team developed a method to draw “forests” of nanotubes out into sheets of aligned fibers and then twist the sheets into yarns-carbon nanotubes are essentially tendrils of tiny, hollow tubes that are super strong and electrically conductive. Next, the group turned to nylon sewing thread and fishing line, which consist of many individual molecules aligned along the fiber’s length. Twisting the thread or fishing line orients these molecules into helices, producing torsional-or rotational-artificial muscles that can spin a heavy rotor more than 100,000 revolutions per minute. When these muscles are so highly twisted that they coil like an over-twisted rubber band, they can produce tensile actuation, where the muscle dramatically contracts along its length when heated, and returns to its initial length when cooled. That research, published in 2014, showed that simple, low-cost muscles made from fishing line can lift 100 times more weight and generate 100 times higher mechanical power than a human skeletal muscle of the same length and weight. “When these fibers are then twisted and coiled, their internal geometry changes so that when they are heated, that diameter expansion results in a change in length,” Baughman said. “The fiber’s diameter only has to expand by about 5 percent to drive giant changes in length.”

In their most recent experiments, described for the first time in the PNAS article, Haines and Li added a new twist to their artificial muscles. Because the coiled artificial muscles were limited in the amount they could expand and contract, they formed the coiled actuators into spirals.

“The advantage to the spiral shape is that now our muscle can contract into a flat state, expand out in the other direction, and return to its original length, all without getting stuck on itself,” Li said. “Our experiments to date have been proof-of-concept, but have already shown that we can use heating and cooling to drive this back-and-forth motion across a giant range. This type of telescoping actuator can produce over an 8,600 percent change in length, compared to around 70 percent for our previous coils.”

Editor’s note: This story was adapted from materials provided by UT Dallas.