One of the most memorable characters in the recent history of U.S. prosthetics was Stephen C. Jacobsen, PhD, the primary inventor of the Utah Arm and the founder of Motion Control, now a Fillauer Company, who passed away in 2016. Three engineers at the nucleus of Motion Control’s research and development (R&D) efforts are alumni of Steve’s lab, Edwin Iversen, MEME, vice president of R&D; and software and design engineers Klaus Biggers, M.S., and Tony Jacobs, BUS.

I was 27 years old in 1975 when I first met Steve, only a year after he finished his doctorate in engineering at Massachusetts Institute of Technology (MIT). It was there that he saw early versions of the Boston Arm and developed his theory of using up to 16 channels of EMG signals to control multiple degrees of freedom in a prosthetic arm. His postulate control theory was the basis of his doctoral dissertation.

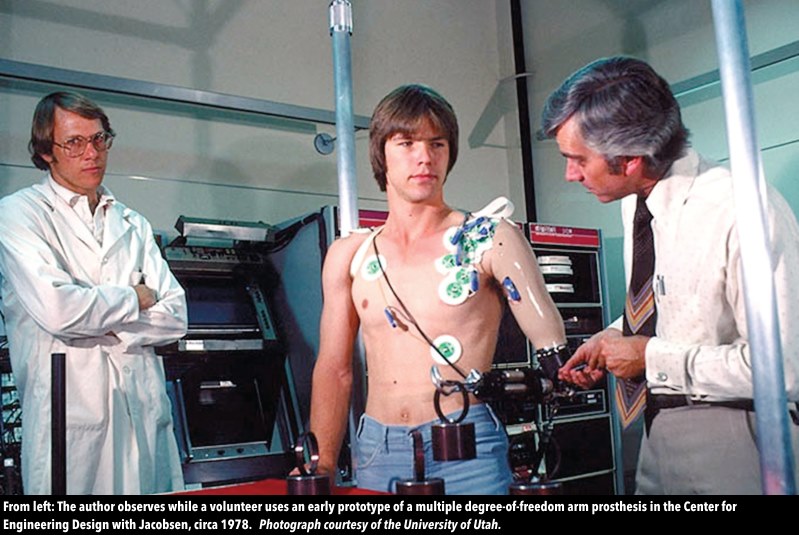

Jacobsen created many first-ever devices, but also founded or made his mark on institutions that continue to this day: He was the director of the University of Utah’s Center for Engineering Design (CED) (where I earned my doctorate); the founder of Motion Control, which remains the only U.S. company that manufactures and designs electronic hands and hooks and manufactures the Utah Arm; and the founder of robotics companies such as Sarcos Engineering. His name is on over 200 patents, and he remains the most successful inventor and entrepreneur from the University of Utah, where he completed his undergraduate degree.

But, for many of us, the most common reminders of Jacobsen are his clever aphorisms, which describe the situation at hand (pun allowed) in a perfect and ironic way. Probably his most repeated quote was created on the spot at the American Academy of Orthotists and Prosthetists Annual Meeting in San Diego, in the mid-1980s:

“One learns right away that prosthetics is a whole lot easier without the patient.”

At first glance this is a facetious statement, but the ironic truth it states reminds us that prosthetics for real patients is a great deal more difficult, but also a great deal more rewarding. Jacobsen felt that prosthetic research had relevance only if it made its way to real users and made a difference to them.

To give some context for the quote, after Motion Control began manufacturing the Utah Arm, Jacobsen’s team moved more heavily into robotics development. Inventions such as the Utah/MIT Dextrous Hand were products of the University of Utah and Sarcos Engineering, and then the team moved on to undersea robotic arms for the U.S. Navy, super-sized industrial robot arms, and animatronic figures for the Disney theme parks, which were remade by Sarcos to be more realistic and more durable. However, Jacobsen always respected the difficult challenges of prosthetics for real people.

I was frequently the guide for tours of the CED, but Jacobsen himself conducted the VIP tours that included such notables as then Vice President George H.W. Bush; Senator Edward Kennedy; DEKA founder Dean Kamen; Dudley Childress, PhD; and Jacobsen’s mentor at MIT, Robert Mann, ScD. The discussion was often expansive, and several times I heard him express:

“Prosthetics is a fascinating area because it’s so rich with issues.”

The applications of engineering in medicine are endlessly fascinating, and the early trailbreakers were inter-disciplinary pioneers, such as Mann, and Jacobsen’s classmate and friend, Woody Flowers, PhD. It was new at the time, but now most engineering departments in the United States offer a bioengineering major. The trade-offs of weight and strength, practicality and aesthetics, cost and reimbursement, as well as the psychological and personal challenges of replacement of a lost limb are all enormously fascinating, and hugely complex—we all felt it was as interesting to us as putting men on the moon was for engineers in the generation before us.

The business of prosthetics is interesting in its own right. I often heard Steve say:

“The same economic processes occur in the prosthetics industry as in other industries, they just happen a lot slower.”

This was a pre-microprocessor prosthetic industry. It was before lithium batteries and smart phones, and carbon fiber feet were just getting started, with a little help from Jacobsen’s lab at the University of Utah where Van Phillips built his first carbon foot.

Another little quip, which was repeated when discussing new product ideas, occurs at that eureka moment when Jacobsen would announce:

“Yes, you have a fantastic idea—and it could make hundreds and hundreds of dollars!”

That particular reality helps to explain why things happen a little slower in prosthetics, compared to, for example, the rapidly changing world of Silicon Valley.

It’s important to remember that Jacobsen was an MIT-educated engineering professor. “Physics does not tell lies,” he would remind us, but the corollary was his alone—a basic truth that we learn (and relearn):

“The principle of the conservation of complexity.”

If, at some point in your life you survived a physics class, you are familiar with the conservation of momentum (or energy), which states that momentum (or energy) is never lost in a system, it is only transferred to other matter or other energy states.

The conservation of complexity states that a device that performs a complex task will have a predictable level of complexity regardless of the design approach taken. Whether an artificial foot or a prosthetic wrist, electric powered or not, a system that does a lot of things will have a high parts count and will have a complex design.

The University of Utah in the 1980s was a place teeming with ambitious and creative minds. But not all ideas could be said to be practical. We dreaded the days, after floating an idea, when Jacobsen would respond:

“We could make that. It could really work. We just need to find some Unobtainium.”

This was an excellent way of bringing an over-ambitious idea down to earth, imagining an element so rare it doesn’t exist, Unobtainium. The term probably came originally from the famous Skunk Works, a Lockheed secret development center for the first supersonic aircraft, where it might have been a synonym for the rare metal titanium, in the early days of supersonic flight.

For all his technical prowess, Jacobsen had an enormous respect for craftsmanship and the value of designing and drawing by hand, with a pencil. He returned from a conference on CAD/CAM, which downgraded the craft of hand-sketching and hand-made prototyping, and reported that he couldn’t help but tell the audience:

“Don’t forget POD/POM: plain old design and plain old machining.”

This is a reminder that there are still opportunities in the combination of old technology with good design. There are many great inventions, and many more to come, that do not involve microprocessors, miniature batteries, or exotic materials. Even the Utah Arm is a hybrid of passive and body-powered components, with the electronics of elbow and hand combined with passive, wearer-activated, humeral rotation and wrist rotation.

But in remembering Stephen Jacobsen, the words I take to heart most are from the 1991 opening session of the conference for the new National Center for Medical Rehabilitation Research institute within the National Institutes of Health. Jacobsen was asked to give a short talk on design and innovation. He ended with this statement, with credit to the words and examples of Thomas Edison, Henry Ford, and the Wright brothers:

“Progress is a process of making mistakes—so get started making mistakes faster.”

Harold H. Sears, PhD, retired in July 2017 as president of Motion Control, a Fillauer Company, Salt Lake City. Sears earned a bachelor’s degree in mechanical engineering and a doctoral degree in bioengineering from the University of Utah and defended freedom as a school teacher in the Peace Corps in Nepal, 1970-71.

Support authors and subscribe to content

This is premium stuff. Subscribe to read the entire article.