A team of engineers from Malaysia has published a research paper in the open-access journal

BioMedical Engineering Online, which presents the design and performance of a new prosthetic socket that uses an air splint system.

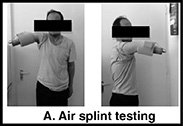

Photograph of the air splint socket courtesy of the study authors.

Fifteen individuals with transhumeral amputations participated in the study. Inclusion criteria consisted of a minimum 12cm residual limb length, no wounds or ulcers on the residual limb, and the flexion/extension ability of the shoulder without the use of assistive devices. The air splint prosthetic socket system was devised by combining an air splint with a pressure sensor that the user controls through the use of a microcontroller. The modular construction of the system allows the pressure sensors that are placed inside the air splint socket to determine the required size and fitting for the socket used. Over a period of three hours, the contact between the skin and the socket fluctuated with an average pressure volume of the air splint of 40 kPa.

Maintaining a good fit is the main objective of the air splint socket system, the engineers wrote in their study, and this system works to automatically adjust the size and fit of the socket. This is particularly important during activities of daily living, they added, and may reduce the pain and discomfort at the residual limb in comparison to a static socket. However, this system cannot be applied to individuals who have a low volume, short residual limb.